Energy Harvesting and Hearing Aids

Trends

Wayne Staab, PhD (Trends) was one of the first audiologists to work with manufacturers back in the 1970s and has a wealth of both historical and current knowledge. His perspectives are balanced and always well thought out.

Powering electronic hearing aids has taken a number of turns over the years – from carbon microphones, through A and B batteries (heater and power battery), other different sized zinc batteries, and finally to cells consisting primarily of mercury, silver, zinc air, and now again, into rechargeable cells.1 The changes in the power supply have resulted from technology that has allowed for the decrease in both the size and power consumption of systems used in hearing aids. The use of current power supplies in hearing aids (most use a single cell today), presents several disadvantages: (1) the need to either replace or recharge them periodically, and (2) the ratio of size and weight relative to the electronics increases, where the power supply absorbs a continued higher ratio of the available building space. The latter is realized as the battery becomes a significant fraction of the total weight and size of the device. Overall, electronic devices that were once considered portable are now being included in everyday use products such as watches, medical condition sensors, glasses, etc., but now generally designed for low power. These disadvantages listed apply to the trend of wearable electronics, in general, but are especially noticeable in existing small wearable devices, such as hearing aids. But, regardless of what product this technology miniaturization pertains to, it continues to rely on an external power supply. A possibility to overcome these power disadvantages is to extract (harvest) energy with either the human or the environment involved. Much of this information has been adapted from Mateu and Moll.2 More recent information is available, but the intent of this post is to lay a framework for understanding the approaches being applied to energy harvesting.

Current Energy Harvesting Approaches

The electrical energy needed to power the electronics is expected to come from one the following energy sources:

- Kinetic

- Electromagnetic

- Thermal

The energy obtained can be used to either recharge a secondary battery, or in some cases, to power electronics directly that require little power and/or current drain. Any approach must realize that the voltage and current generated is transient and discontinuous, and therefore has to be converted into a DC signal, requiring a converter and/or storage circuit.

Is Energy Harvesting Realistic for Hearing Aids?

Although performing as a method to power a hearing aid may be some time in the future, use of harvested power to periodically perform a maintenance function is more likely to be the initial action. The author has already been contacted relative to such an approach by engineer designers from outside the hearing aid industry. Is it possible to design hearing aids having different low power or sleep modes that would save energy during times of inactivity? Or, could some energy harvesting be done to help “refill” the energy tank (battery) during such times of low activity? Either of these approaches would require harvesting on a discontinuous mode unless some sort of energy storage is designed. And, an ideal design would not consume any fuel or substance from the host battery (this is called Direct Energy Conversion).

How Can Energy Harvesting Occur?

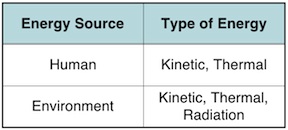

Classes of energy harvesting devices are identified in Figure 1. These are based on who or what type of energy is converted.

Figure 1. Classes of energy harvesting devices

This categorization follows the first law of thermodynamics (a version of the law of conservation of energy) in that a greater amount of energy must be spent to obtain a certain amount of electrical energy. A first explicit statement of this law was by Rudolf Clausius in which he stated:

“In all cases in which work is produced by the agency of heat, a quantity of heat is consumed which is proportional to the work done; and conversely, by the expenditure of an equal quantity of work an equal quantity of heat is produced.”3

In the case of human energy power source, the user, in one way or another, provides this energy, recognizing that the energy levels are very small, and just kinetic and thermal energy are available. Human kinetic energy can be generated either passively or actively, with the former taking action specifically to generate energy, or the latter to use casual movement during normal behavior. Thermal human energy, on the other hand, is always passive. Environmental energy can be borne of kinetic energy from vibrations, radiation as solar energy or RF (radio frequency) radiation, or thermal energy existing because of temperature gradient. A greater in-depth presentation of thermal energy in the form of body heat (Part 1 and Part II) can be found at Hearing Health and Technology Matters (http://hearinghealthmatters.org/waynesworld/2013/future-hearing-aid-power-supply-body-heat/ Part I,1 and http://hearinghealthmatters.org/waynesworld/2013/hearing-aid-power-supply-body-heat-ii/ Part II).4

Examples of Harvested Energy

Human Energy Harvesting

Human active energy – radio receivers, wristwatches, flashlights, and battery chargers (winding a crank handle or shaking the device as kinetic energy). Human passive energy – attachable medical devices, electric wristwatches, heat sensors. These generally involve a thermoelectric generator that converts body heat flow into electricity. In some cases, a piezoelectric ceramic can be bent to generate energy. Depending on how it is accomplished, it could fall into either of the above two categories.

Environmental Energy Harvesting

Kinetic energy results from displacement of a moving part or the mechanical deformation of some structure within the energy-harvesting device. This displacement/deformation can be converted to electrical energy by three methods:

- Piezoelectric material

- Electrostatic energy

- Magnetic induction

Piezoelectric Generation – uses the piezoelectric effect discovered by Jacques and Pierre Curie in 1800. They found that certain materials, when subjected to mechanical strain, resulted in electrical polarization proportional to the applied strain. Compression, slapping, and bending can excite the piezoelectric material. Electrostatic Generation – involves the moving part of a transducer moving against an electrical field, thus generating energy. Magnetic Induction Generation – is based on Faraday’s law, where a variation in magnetic flux, through an electrical circuit, causes an electric field. In this, the size of the coil is inversely related to the obtained electric field and thus, to the generated energy.

Electromagnetic Radiation Harvesting

This form of energy harvesting generally occurs in the form of light (solar), or lower frequency RF radiation. Solar Energy Radiation – varies according to location and local weather conditions. A PV (photovoltaic) system can have a wide range of power and applications, from wristwatches to power grids. RF Radiation – operates by directing high power electromagnetic energy to a device from a nearby source. Large populated areas have a number of potential RF sources (Radio, TV, mobile telephone, wireless networks, etc.). However, the actual energy levels present are too low for present electronic devices, even if the difficulty of collecting and converting them into energy could be solved.

Thermal Energy Harvesting

This was the thrust of the two articles mentioned previously by Staab.1,4 Thermal energy is readily available in the environment – available from humans, animals, machines, or other natural sources – anywhere a differential exists between the temperatures of two elements/features. A thermogenerator (based on the Seebeck effect) produces an electrical current proportional to the temperature difference between the hot and cold junctions (hot and cold are relative terms, merely differentiating between two different temperatures). An upper limit (Carnot Efficiency) exists on the heat energy that can be transferred. For the human body and the environment at room temperature, the Carnot Efficiency is estimated at 5.5%. This efficiency percentage would drop in warmer environments and increase in colder environments. However, evaporative heat loss can account for 25% of the total heat dissipation, meaning that the overall maximum power available would not be as high as estimated.

Future

Energy harvesting to function as a power source for electronic devices is an active area of research. At this time, none of the approaches provide more than a low level of energy compared to the power requirements of today’s electronic devices, except for specific applications. And, hearing aids do not fall into the specific applications department where this has been accomplished. How rapidly energy harvesting advances will most likely depend on new transducer designs, new materials, innovative power conditioning circuits, and energy storage. Based on the monumental differences in battery advancement against electronic technology over the years, the best bet is on electronic technology evolution to decrease energy consumption due to continuing scaling down of devices, nanotechnology, and eventually, molecular electronics.

References

- Staab W Hearing aid power supply – body heat? Part 1; 2013 Available at: http://hearinghealthmatters.org/waynesworld/2013/future-hearing-aid-power-supply-body-heat/.

- Mateu L, and Moll F. Review of energy harvesting techniques and applications for microelectronics, Proceedings of SPIE, VLSI Circuits and Systems II, June 30, 2005, Sevilla, Spain; 2005.

- Clausius R. (1850), page 373, translation here taken from Truesdell CA 1980;188–189.

- Staab W. Hearing aid power supply – body heat? Part II; 2013 http://hearinghealthmatters.org/waynesworld/2013/hearing-aid-power-supply-body-heat-ii/.