Acoustical Materials

From Google:

“Acoustical materials are a variety of foams, fabrics, metals, etc. used to quiet workplaces, homes, automobiles, and so forth to increase the comfort and safety of their inhabitants by reducing noise generated both inside and outside of those spaces.”

It is not unusual for people to “Google” to satisfy their curiosity or learn about something in a “quick and dirty” way. There is nothing wrong there, provided the reader is aware of the limits of the search engines they are using.

So, what are acoustical materials? If we want to be rigid, the answer is there is no such thing! They are materials used for acoustic or, more precisely, for noise control purposes. Those materials can be of two kinds: sound absorbing and noise insulating. The two are entirely different from the other in their physical characteristics and their use and applications.

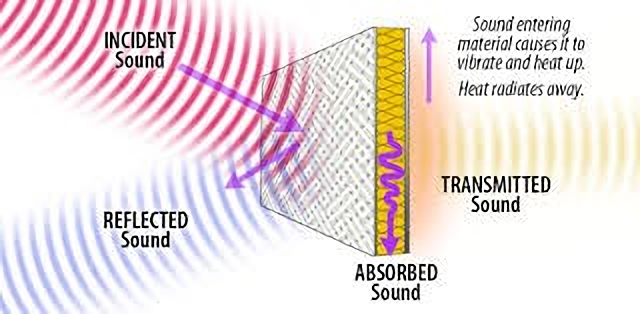

When a sound wave impinges upon an obstacle (e.g., a wall), three phenomena occur: part is reflected back, part is absorbed by the obstacle and transformed in heat, and the rest is transmitted through the obstacle (see Figure 1). The amount of the incident sound energy absorbed and transmitted depends on the obstacle’s physical properties.

Sound insulating materials (also known as soundproofing) reflect most of the energy back and partially block the transmitted energy. They are heavy and impermeable. The best examples are cement blocks and bricks. Glass and drywall are other examples of materials widely used in the construction industry.

Sound absorbing materials, in contrast, absorb most of the incident energy. They are soft, light, and fluffy. Sound waves penetrate those materials. Air molecules are set in motion by the waves, rub against their fibres, and transform kinetic energy into heat. As a result, very little energy is reflected back. Examples are open-cell foams, carpets, and acoustic tiles.

The use of sound-absorbing materials plays an essential part in optimizing the acoustical quality of any enclosed place used for music and speech, such as auditoriums, classrooms, or theatres. They are used to adjust the reverberation time and ensure optimum intelligibility of speech or music quality.

| Sound Insulation | Sound Absorbing |

| Heavy and impermeable | Light and fluffy materials |

| Typical attenuation on the order of 25 dB | Used primarily to improve reverberation |

An audiometric sound booth is an excellent example of using both kinds of materials. The outside shell is meant to be sound-insulating. In most cases, it is made of metal to reduce the sound that penetrates the cabin. The interior of the booth (walls and ceiling) is lined with sound-absorbing material. In most cases, they are acoustical tiles that absorb part of the transmitted energy and further reduce the interior sound level. A thick carpet ensures that a minimal amount of sound is reflected by the floor.

How much noise is reduced using either type of material? When insulating an enclosure using proper sound insulating materials and good building practices, it is relatively easy to reduce the noise by up to 25 dB. However, using sound absorption, the maximum theoretical noise reduction does not exceed 10 dB, while it rarely exceeds 5 dB in practice. So, those materials should not be used for noise control but the control of the reverberation and the acoustics of enclosed spaces.

To summarize, there are two kinds of materials used for acoustic purposes. The heavy, solid materials are used to reduce the sound level, while the light and fluffy materials are reserved mainly for improving the interior of an enclosed space.