The Sound of a Motorcycle…Three Points of View

Reprinted from Noise News International. Used with permission

There are few other sources of sound that generate as far reaching an emotional impact as the sound of a motorcycle. The sound of a motorcycle is shaped by many influencing factors and to be a successful product it has to meet the requirements of three distinct and often conflicting perspectives. Motorcycles have to meet government noise regulations that specify the maximum amount of sound that can be generated under certain conditions; the user requires their motorcycle to generate a certain emotional and visceral response and finally the manufacture has to design a product that balances all of these often-conflicting requirements in an economically viable product.

The goal is to meet all local, state, and federal sound regulations as they relate to motorcycles, offer the consumer a stimulating and exciting product and be economically viable to the manufacturer. This includes motorcycles classified as road legal vehicles and those classified as off-highway vehicles (OHV). This is a delicate balance the acoustical engineer strives to achieve.

The Sound of a Motorcycle from a Regulatory Point of View

Original equipment motorcycle manufacturers (OEM) must comply with not to exceed maximum noise levels usually measured in dBA at the time of sale. In addition, in-use noise requirements have been established by various communities to limit the noise impact on community residents. The test procedures used to comply with legislative noise requirements vary by location and consist of testing the motorcycle in motion, referred to as a pass-by test, or with the motorcycle at rest, referred to as a stationary test, or both. Each location usually specifies not only the allowable noise level but the manner in which the vehicle is to be tested. For instance, a pass-by noise test requirement might specify the surface the motorcycle must drive on, the distance the microphone is from the centerline of travel, the vehicle speed, engine RPM, the transmission gear at which the vehicle must enter the test zone and the throttle condition or acceleration rate the vehicle must experience during the testing process. Also, the normal environmental conditions to ensure an accurate and representative noise test must be followed. Pass-by noise testing can be a costly undertaking. In addition to the cost of sophisticated instrumentation, a test track has to include a large tract of land with acceptable ambient noise levels and the driving surface must be designed to have specific acoustic absorption characteristics. The weather at the test site is a major factor and may limit the testing window. To counter these drawbacks, several manufacturers have developed in-door pass-by testing chambers costing millions of dollars with excellent correlation to outdoor testing results.

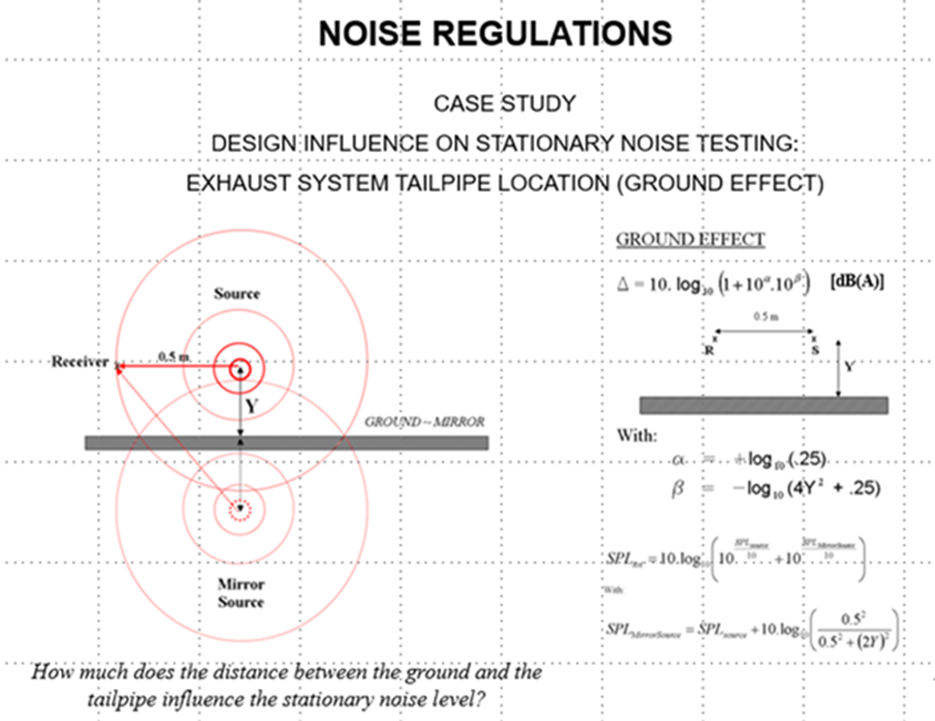

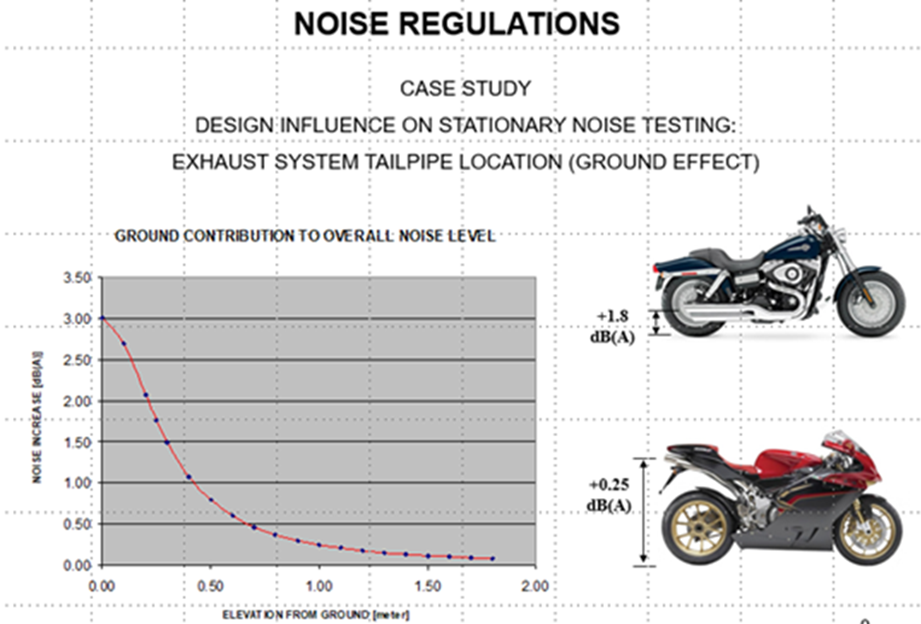

A stationary noise test also has its own set of specific operating conditions. The position of the microphone relative to the motorcycle exhaust and the engine speed (RPM) are two important parameters to be followed. Community noise ordinances set to limit the amount of sound produced by a motorcycle rely on stationary noise tests as a simple yet accurate way to control in-use motorcycle noise levels. A stationary noise test is designed to measure exhaust dominate sound because of the placement of the microphone. The location of the exhaust outlet relative to the ground (a reflective plane) can have a significant influence on test results. Figures 1 and 2 show the theoretical and actual influence of this reflective plane on exhaust sound levels for different style exhaust systems.

Street legal motorcycles may exceed allowable noise levels due to tampering of the vehicle’s original intake or exhaust systems. Changing exhaust and intake components are the usual culprits in raising a vehicle’s sound level. Some locations have yearly vehicle inspections to identify noise increasing modifications. Other locations may have roadside inspections that can be effective in identifying tampered exhaust systems. However, this has generated complaints from riders as some aftermarket systems are equivalent to original design and may be noise compliant. These compliant systems should be stamped with the appropriate certification marks, and the examining official needs to look for them before issuing a citation.

The noise level of a motorcycle in use can be significantly influenced by operator behavior. Aggressive riding habits could generate excessive noise from speeding on public highways or revving the engine beyond normal RPM ranges. Police monitoring to identify riders who exceed posted speed limits, rider education such as rider training, TV advertising, radar signs that have vehicle speed reading capabilities etc., all help to alleviate this issue.

The old saying “Less Sound means More Ground”, a popular off-road statement, also applies to street riding. Maintaining reasonable sound emission will reduce complaints of motorcycle usage to a minimum.

Motorcycles designed for (OHV) use pose an additional challenge to manufacturers, local governments, and riders. “Not in my backyard” is a frequent comment when a community learns of a proposed OHV recreation area. This can be related to issues such as noise, zoning, perceived property value impacts, dust, vehicle traffic, lack of parking, and associated activities such as, unlawful camping, partying late into the evening, and playing loud music.

Another issue centers around vague local and state noise regulations. Local regulations are many times lacking in detail or use a general “nuisance” concept to control noise. It is not unusual for a test procedure to lack measurement detail ( Linear, Leq, L50 or L90, A weighting etc.), the type of sound level meter to use or even the calibration requirements. Careful research into what the test requirements are is an required.

Many local nuisance noise regulations are somewhat subjective and do not use an industry recognized test procedure. In such case, using the Federal Housing and Urban Development 24 CRF Part 51 Regulation for High Density Residential Areas may be useful.

The Sound of a Motorcycle from the Riders Point of View

The motorcyclist wants to establish an emotional connection with their motorcycle. Each motorcycle has its own distinctive characteristics that attract the rider. It may be the visuals or the performance but for some motorcyclists it is the sound that makes the attraction. Riders want to establish an emotional connection to their bike and for many it is the sound quality. What might be music to the ears of one can be an unnerving source of irritation to another and the same is true for motorcycles. The distinctive sound of a Ducati 999 or BMW R90 is measurably different from the rumble of a Harley Davidson cruiser or the whisper of a Honda Goldwing. To meet the sound quality expectations of the rider there are certain guidelines when designing the motorcycle that should be considered. To meet the expectations of the rider one must identify and quantify the sounds the rider likes and dislikes. There are positively perceived motorcycle sounds and there are negatively perceived motorcycle sounds from the user’s point of view. The negative sounds include driveline sources such as ticks, knocks, whines, clatter, and rattle. Undesirable chassis sounds include the list of BSR (buzz, squeak, and rattle) offenders. In addition, cooling fans, fuel and water pumps, relays, tire noise and excessive intake honk along with ear shattering exhaust noise need to be addressed.

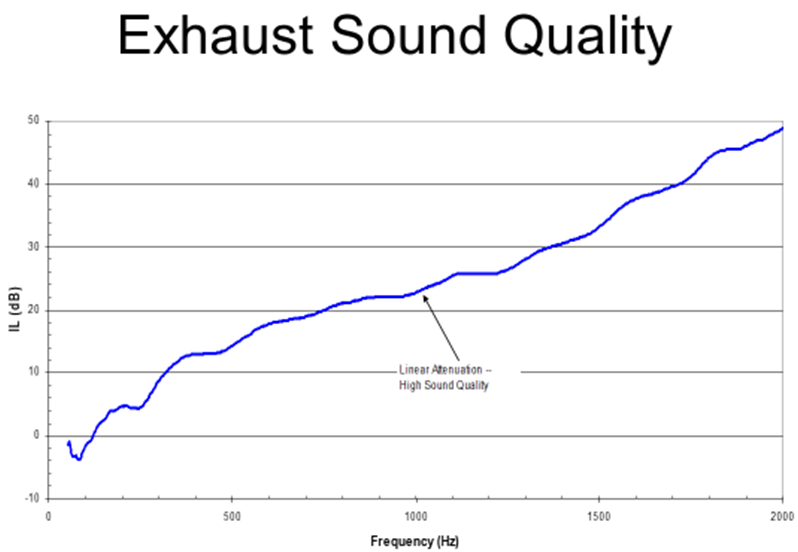

Desirable sound quality items include smooth consistent mechanical noise without sharp resonances, progressively increasing ICE (intake, combustion, exhaust) sound during vehicle acceleration. Some riders expect a dominant exhaust note or a syncopated idle sound (potato, potato, potato). This sound quality has to be balanced to meet regulatory requirements while emphasizing the sounds riders like and minimizing the sounds rider’s dislike. Although regulatory noise compliance dictates the upper sound level limits, the character defining sounds need to be determine and development actions taken to ensure they are achieved. Sounds need to be purposeful and indicative of the quality. Figure 3 is an example of an exhaust sound that meets the sound quality expectations of one class of riders. Certain manufacturers have developed their own sound quality metrics based on customer jury testing as a guide to developing model specific sound quality packages. One manufacture applied to trademark their sound with the US Patent and Trademark Office.

Electric motorcycles (EVs) are not immune from sound quality issues and present a unique sound quality challenge. Although there is a lack of combustion (intake and exhaust) the sound of the driveline become the dominant noise source. Tonal frequencies should be adequately spaced to minimize dissonance. Whines and resonances should be understood and controlled to keep from becoming annoying or excessive. The effect on sound quality should be considered during every phase of development including items such as the drive line belt tension. The rider should experience audible feedback when the vehicle is energized, and locomotive power is available.

The Sound of a Motorcycle from a Manufacturer’s Point of View

The job of a motorcycle designer is to take the competing requirements and expectations from regulatory, the rider, society and manufacturing and develop a product that satisfies all. The packaging constraints, manufacturing complexity and economics of meeting these requirements can be staggering and not always successful. The delicate balance among all of the stakeholders is many times thwarted by the end user installing aftermarket equipment that skews this balance with the moto “Loud Pipes Save Lives”

The motorcycle exhaust system is a critical component in defining the performance, styling, and sound quality of the motorcycle. Packaging constraints, weight, styling, and cost are all considerations that are assessed in exhaust system design. Some of the design challenges are regulatory requirements, tonal quality, engine tuning, emission control, cosmetic finish and structural durability all wrapped around cost.

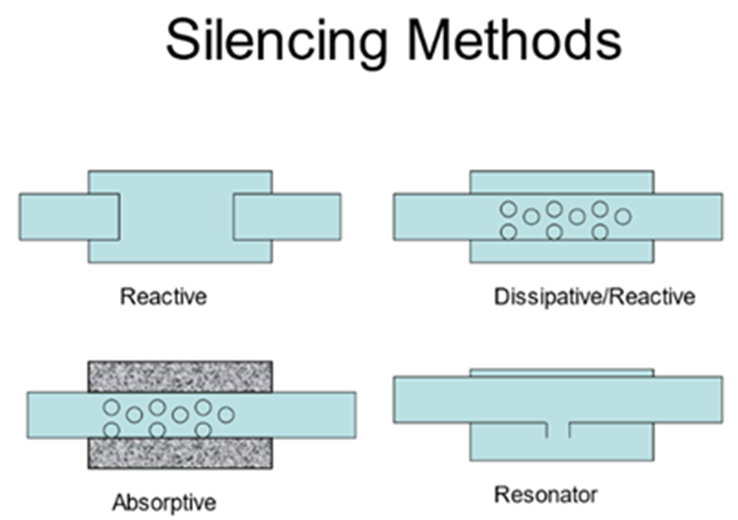

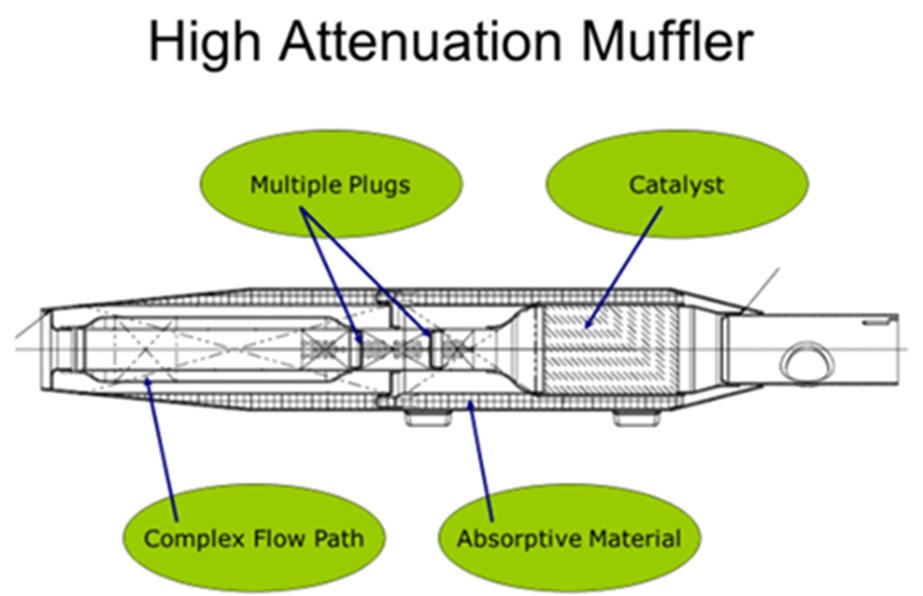

There are various predictive tools that can be used to optimize the performance of an exhaust system for both sound and engine performance. Some of the typical silencing approaches are listed in Figure 4 and each one comes with its pros and cons. A basic muffler design may include a perforated tube and plug whereas a more complex design could include all four acoustic elements along with tail pipe emission control technology as shown in Figure 5.

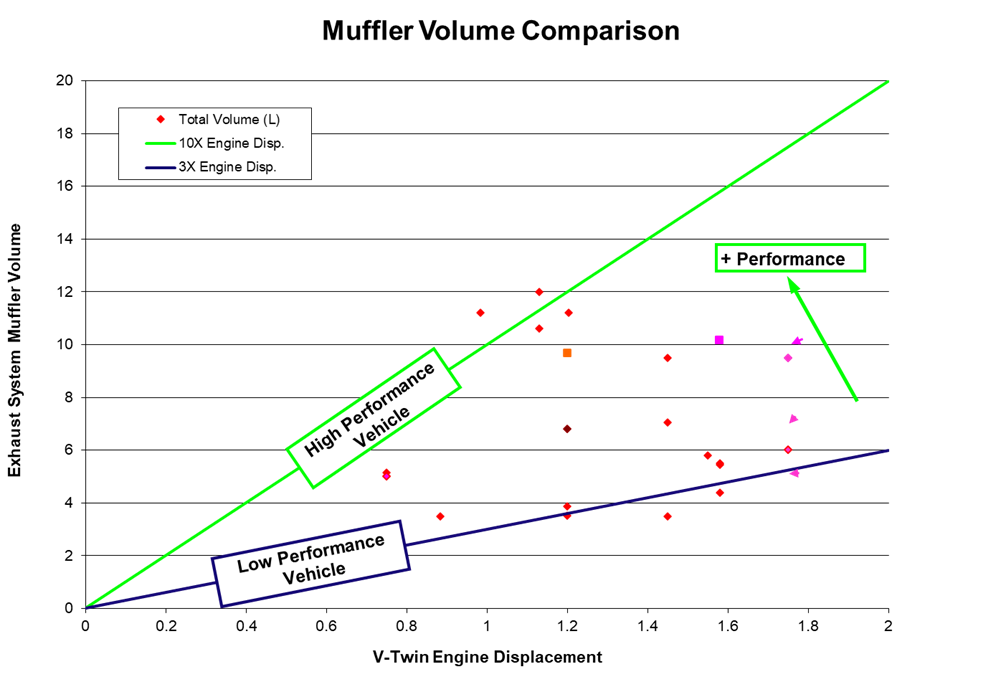

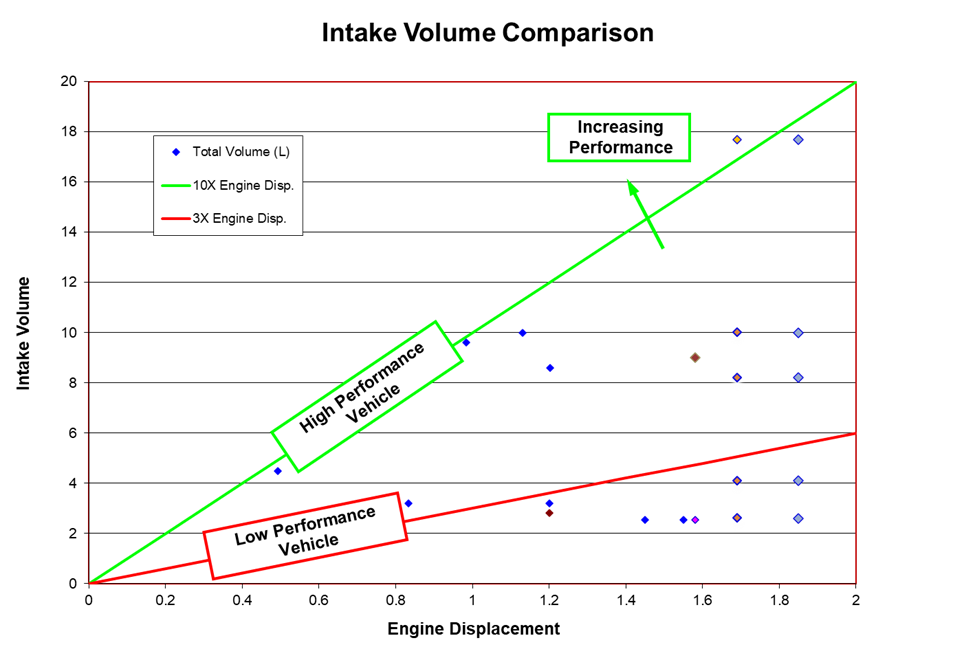

There is a multifactor relationship among engine performance, exhaust system volume and sound level. As the size of the exhaust system increases, the relative engine performance increases and the overall sound level decreases and conversely. Figure 6 shows the empirical relationship between engine performance and exhaust volume for a noise legal system. Noise legal high-performance motorcycles may have a minimum of 10:1 ratio of exhaust to engine volume whereas a cruiser style motorcycle would be much less. Aftermarket exhaust systems that forego this relationship are typically non-compliant. An exhaust system with good sound quality exhibits a linear insertion loss across a frequency band. There is a consistent increase in sound level with engine RPM and there are no significant resonances. The intake system of a motorcycle also requires a significant amount of design expertise to achieve similar operational goals. Contrary to exhaust sound, the sound of an intake is usally not desireable and subtracts from the overall sound quality of the vehicle. Using predictive tools to optimize airflow and acoustical insertion loss intake noise can be designed out of the sound quality recipe. Similar to the exhaust system the volume of an intake system does have a direct effect on vehicle performance and sound level. Figure 7 is a graph of intake volume and engine displacement.